How the FlowlineProSS system works

A new level of accuracy and user-friendliness, with direct, online access.

Overview

FlowlineProSS and FlowlineProTransient are advanced software tools designed for comprehensive flow assurance studies. They support simulation of single-phase, two-phase, and three-phase flow in both standalone pipelines and complex network configurations.

FlowlineProSS: Cloud-Ready Steady-State Simulation

The steady-state module, FlowlineProSS, is fully production-ready. It is deployed in the cloud and accessible via any modern web browser. It is primarily used during conceptual flow assurance studies in the PRE-FEED and FEED phases.

Computational Innovation

FlowlineProSS leverages a pioneering computational framework that integrates:

- Mechanistic modeling at the forefront of flow assurance science.

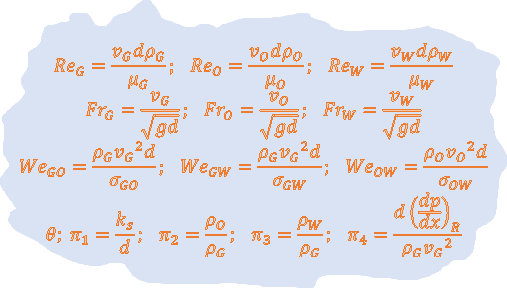

- Extended dimensional analysis, accounting for all relevant physical parameters.

- Neural network architectures for enhanced predictive capability.

By uniquely combining all three scientific domains, FlowlineProSS stands as the only flow assurance simulator to achieve this level of integration—broadening its applicability and yielding more reliable, data-driven results.

Specialized Capabilities

In addition to traditional flow assurance features, FlowlineProSS introduces:

- A novel slug-limit curve plotting tool, enabling engineers to explore strategies for mitigating slugging without requiring complete avoidance.

- An advanced erosion calculation module, allowing users to define scientifically grounded maximum velocity limits—optimizing production while extending field life and maintaining safety.

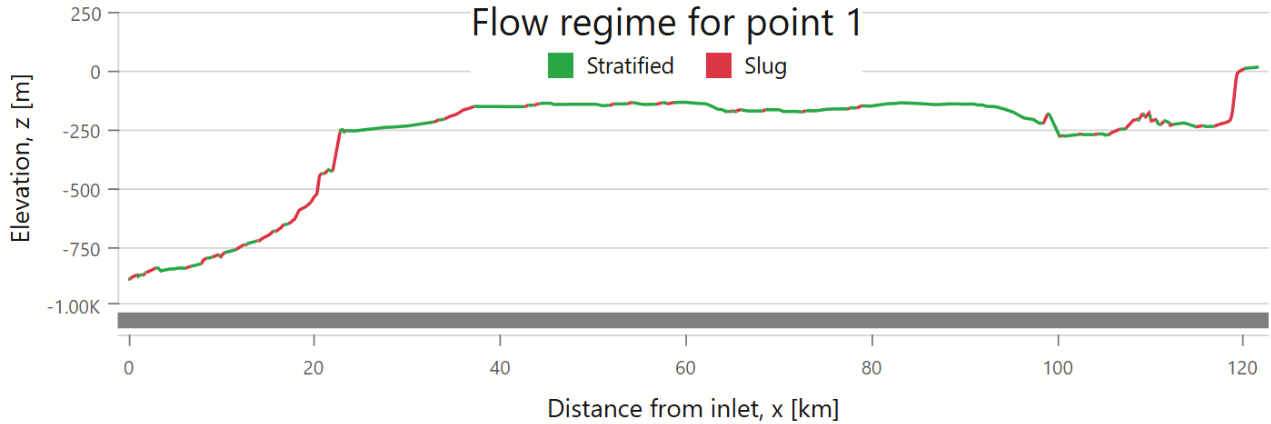

- A dynamic flow regime plotter, illustrating realistic 3-phase flow regimes that often diverge significantly from those predicted by models that overlook the foundational constraints of the Buckingham π theorem.

To demonstrate real-world applicability, the software includes pre-configured examples replicating actual configurations from some of the most renowned subsea installations globally.

Working Online

Since FlowlineProSS is hosted in the cloud, it can be accessed directly through any modern web browser, such as Google Chrome or Microsoft Edge.

This cloud-based deployment offers several key advantages:

- No installation required – Begin using the system immediately after your license is activated.

- Effortless setup – Simply follow the built-in guidance to get started with minimal hassle.

- Device flexibility – Even low-spec computers can run the interface smoothly, as all intensive computations are performed in the cloud.

- Responsive interface – The browser view can be zoomed and adjusted to fit any screen size, ensuring a comfortable user experience.

- Expert support – Our highly qualified specialists are available to assist with system configuration and any Flow Assurance-related inquiries.

All generated files and results can be securely downloaded to your local machine for safekeeping and further analysis.

Background

FlowlineProSS, developed by Dr. Ove Bratland and his team since 2005, builds upon the foundation laid by its predecessor, FlowlinePro.

While elements of the software’s theoretical framework are documented in Dr. Bratland’s widely adopted textbooks Pipe Flow 1 & 2, the methodology has evolved significantly. This advancement stems from ongoing theoretical research and experimental validation conducted in collaboration with various organizations, not least the National University of Singapore and Prof. Zaichik at the Nuclear Safety Institute of the Russian Academy of Sciences in Moscow. The resulting insights are supported by a broad spectrum of academic publications, technical papers, and especially instructional materials designed for students.

These resources have been used extensively in both university-level teaching and industry consulting, forming the backbone of training programs, engineering workshops, and real-world advisory projects across multiple regions and operating environments.

A major breakthrough occurred in 2011, when the integration of three advanced scientific disciplines—mechanistic modeling, neural networks, and comprehensive dimensional analysis—successfully bridged many of the long-standing gaps in flow assurance modeling.

Unlike conventional models that focus on isolated subsets of variables, the new dimensional analysis framework accounts for all relevant physical parameters affecting the flow simultaneously, enabling a complete and coherent representation of the governing relationships.

This innovation addressed a long-standing challenge in the field: the inability to intelligently scale laboratory-based measurements to full-sized flowlines. By resolving this, the model enabled neural networks to be trained with sufficient accuracy to substantially enhance the automatic calibration of the underlying mechanistic models.

Several core modules from FlowlineProSS are also embedded in operator-training simulators for subsea multiphase flowlines, and are actively used in academic settings.

Over the past five years, FlowlineProSS modules have powered pipeline-operator simulators at PEMEX’s Centro de Adiestramiento en Procesos de Producción (CAPP), deployed by Rheinmetall AG under license from Dr Bratland Flow Assurance Systems Pte. Ltd.

These modules—responsible for advanced flow-regime and friction calculations—represent earlier iterations of the technology now featured in FlowlineProSS. The current version is further enhanced by including some of the work in Ref. [6], refined through collaboration with Prof. Zaichick.

Traditional and new features

FlowlineProSS offers the standard steady-state simulation capabilities found in conventional tools, but with a new level of user friendliness. Users can visualize flow behavior under varied design and operating conditions, carry out detailed and targeted slugging analyses, and apply erosion-driven fluid velocity limits grounded in scientific precision and economic insight.

Additionally, FlowlineProSS provides specialized modules for mitigating slugging during startup and low-flow scenarios late in a field’s lifecycle.

Smarter Slugging Studies

Limitations of Turn-down Curves

Traditional early-phase slugging analyses often rely on turn-down curves, which identify the flow rate that minimizes pressure drop. These curves typically suggest avoiding operation below this threshold. FlowlineProSS can automatically generate turndown curves for initial assessment.

However, turn-down curves have notable limitations: They do not indicate whether slugging occurs, nor whether slugs will propagate to the outlet and impact the inlet separator—an essential consideration for system stability.

Slugging at low flow rates, unavoidable during startup, requires focus even in early design studies.

Moreover, as well pressures and flow rates evolve over time, operational procedures—and often the system design itself—must adapt accordingly. Turn-down curves offer only limited practical guidance for managing these dynamic conditions.

Slug-limit Curves: A Smarter Alternative

FlowlineProSS introduces slug-limit curves, which provide a more targeted and actionable approach to slugging analysis. Rather than focusing solely on pressure drop, slug-limit curves reveal:

- Where slugging occurs within the flowline.

- Whether it poses a risk to downstream equipment.

- What inlet and outlet pressures are required to manage different flowrates.

This method enables engineers to identify operating conditions that prevent slugs from reaching the outlet, without requiring slug-free flow throughout the entire system.

Without the need for extensive simulations, it also reveals how adjusting outlet pressure during late field-life stages can significantly prolong production—often achievable by installing an outlet compressor to stabilize flow at reduced rates.

Velocity Limits

Superior criteria

Velocity limits based on erosion risk are essential for both flowline design and operational efficiency.

FlowlineProSS promotes a more advanced and practical approach to establishing these limits than what is commonly applied.

The widely used API RP 14E “never-exceed” velocity guideline is straightforward, but it overlooks many - even most - of the key parameters known to influence erosion.

It is also too inflexible to accommodate the varying velocity requirements across different stages of a field’s lifecycle. As a result, this approach tends to impose unnecessary economic constraints.

FlowlineProSS instead applies more nuanced criteria from DNVGL-RP-O501, delivering a smarter, scientifically grounded balance between safety and system performance.

Operational Impact

In the later stages of a field’s life, declining flow rates can lead to slugging—sometimes forcing premature shutdowns, especially when installing slug catchers or large separators are not feasible.

Reducing outlet pressure via topside compressors can help increase velocities and mitigate slugging risks, and it also increases the production rate. However, operating at higher velocities demands a more detailed understanding of erosion potential.

FlowlineProSS’s erosion module is essential for evaluating such strategies, enabling operators to make informed decisions that can extend production, optimize economics, and maintain system integrity.

Getting Started

Many users find traditional simulators difficult to navigate, often struggling to determine where specific input data should be applied and why certain entries are rejected.

FlowlineProSS is from the ground up designed to emphasize clarity and usability, providing intuitive feedback at every stage of the modeling process:

- Visual indicators (orange/green) show which input data has been validated.

- Built-in tooltips provide instant descriptions when hovering over any on-screen element.

- Real-time prompts guide users when simulations fail or require adjustment.

- Integrated help buttons link directly to the relevant user manual section for deeper support.

Summary of the FlowlineProSS Experience

User-focused design

FlowlineProSS emphasizes usability, offering automatic feedback at every stage—from system definition to simulation and plotting.Effortless onboarding

The platform is fully web-based, allowing users to get started immediately. When needed, leading experts are available to provide support.Advanced dimensional analysis

A proprietary model has enabled the upscaling of laboratory-scale measurements to full-scale field conditions, enhancing the reliability of the simulation model.More than a traditional simulator

FlowlineProSS combines with extra tools, including slug-limit curve functionality, an advanced erosion module, and several types of flow regime plotters.